with excellent containment facilities

Overview

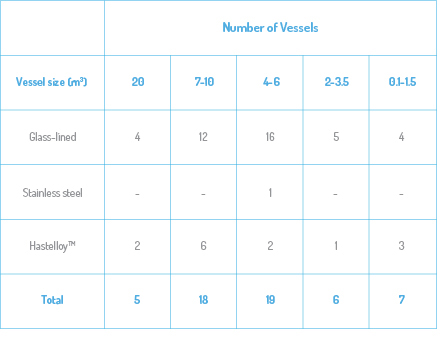

Lianhetech Seal Sands has 4 workshops housing over 370,000L reactor capacity. Each workshop is designed with multi-purpose assets so it can be quickly reconfigured to suit a wide range of processes at a minimum of cost.

Workshops 1 and 2 offer a range of vessels from 4,500L to 13,600L in both Hastelloy™ and Glass Lined Mild Steel

Workshops 1 and 2 offer a range of vessels from 4,500L to 13,600L in both Hastelloy™ and Glass Lined Mild Steel- Workshop 3 offers a range of larger vessels up to 20,000L in both Hastelloy™ and Glass Lined Mild Steel

- Workshop 4 has pilot plant facilities from 100L up to 4500L in both Hastelloy™ and Glass Lined Mild Steel

Solids isolation is carried out on a range of stainless steel, Hastelloy™ and Halar™ lined centrifuges and filter-driers.

Core Capabilities

- Normal operating range of -30°C to +140°C

- Specialist equipment from-85°C to -40°C for our cryogenic plant and up to +180°C for other specific equipment

- Operating pressure ratings from full vacuum to 8 bar

- Nitrogen delivered to the points of use by a validated supply system

- Laminar flow booth, AJAX and DEC charging systems

- Siemens PCS7 DCS control

Pilot Plant

With vessels from 113L in Hastelloy™ and glass-lined steel, the pilot facility offers excellent flexibility over a wide range of chemistries for both solid and liquid products.

-

Extensive experience in handling hazardous substances

-

113-4500L scale in hastelloy and glass-lined steel

- Cryogenics at -85ºC

-

Range of pressure filters, centrifuges and driers

- Glove box facilities for final product handling

-

High temperature distillation - 30 plates

-

Sucessful FDA general systems audit in February 2017

Specialised Equipment

- Chlorination (as chlorine gas)

- Cryogenic facilities (ca -85ºC)

- Fractional distillation

- Continuous Reactors

- Glove Box Technology for charging and discharging

- HEPA Filtration facilities

- Hydrogenation (5000L Hastelloy™and 9000L glass-lined steel)

- Ozonolysis

- Purified Water

- Thiophosgenation

- Other Specialised Equipment

Isolation

Product Isolation

At Lianhetech Seal Sands we have a range of isolation, drying and separation equipment:

Solid Isolation

- Filters and filter driers: Rosenmund (316 stainless), Cogeim (Hastelloy™), Charles Thompson (Hastelloy™)

- Centrifuges: Heinkel (Hastelloy™), Ferrum (PTFE lined), Broadbent (Stainless and Halar™ lined)

Material can then be charged into a range of driers:

- Paddle driers: Lodige (Stainless), Buss (Stainless)

- Rotary Cone Driers: Pfaudler Balfour (Glass-Lined)

If required, we also have sieving and milling facilities

Liquid Isolation and Separation

- Stainless steel batch stills and high vacuum glass still

- Hastelloy and stainless steel Luwa wiped film evaporators

Waste

Lianhetech Seal Sands has direct pipeline access to one of the largest municipal liquid aqueous waste disposal facilities in Europe at Northumbrian Water’s Bran Sands facility.

Lianhetech Seal Sands has direct pipeline access to one of the largest municipal liquid aqueous waste disposal facilities in Europe at Northumbrian Water’s Bran Sands facility.

Our sister company, Fine Environmental Services, operates one of only three, third party licensed, high temperature thermal oxidisers for incineration of other waste streams e.g. halogenated, organics or contaminated aqueous streams.

We also have excellent transport links which allows easy road haulage of other materials that are not suitable for our on-site facilities.

Warehouse

We have broad regulatory consent for storage of a wide range of materials in both bulk and drums.

We have broad regulatory consent for storage of a wide range of materials in both bulk and drums. - A fully-fenced site with comprehensive CCTV coverage.

- 24/7 site-based security and access control give us the ability to store and distribute Controlled Substances.

- Specialised temperature-controlled storage in the range of -15°C to +30°C extends our capability.